WHO WE ARE

New Technologies define New Standards

We at PMT Powder Maker Group GmbH are specialists in the field of dry fine grinding of organic materials as well as soft to medium-hard industrial minerals with a high aspect ratio.

Micronized industrial minerals such as Talc, Mica, Graphite, Zeolite, Wollastonite, Barite or Micaceous Iron Oxide are main components of plastics, papers, paints, cosmetics, pharmaceuticals and many other products of the daily life influencing their required properties.

Besides the type of material also the particle size and the particle shape described by the aspect ratio have a substantial influence on the properties of the specific final product.

As consumers demand higher quality products, product developers are put under increasing pressure to develop materials that perform better, therefore customers are looking to mineral fillers and functional additives to give the required results.

In this field we are one of the leading companies in the field of dry grinding and classifying of industrial minerals to the finest end.

We have set new standards both in energy efficiency as well as fineness to reach the natural given limits in dry material processing.

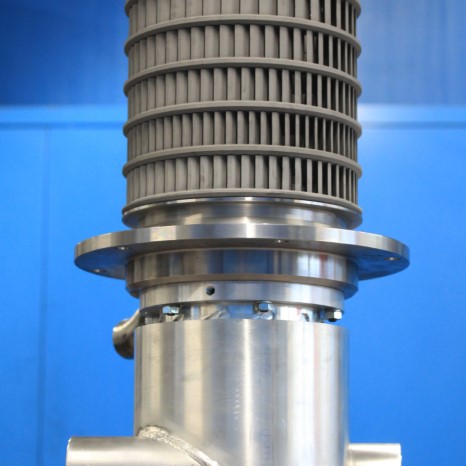

All machines have the integrated dynamic classifier, the so-called Rotor-Motor-Unit. Mounted on our in house developed high-speed motor we have classifier disks made of high strength aluminum alloy to allow circumferential speeds of up to 190 m/s.

With these products a fineness down to the low micrometer range and depending on the material even below 1 µm can be achieved.

With the newly developed EEU System “Enhanced Energy Utilization” the specific energy consumption could be reduced by up to 30 % compared to other micronizing equipment.

For customers, who have capacity constraints or want to produce samples for a new market approach, we offer the possibility to grind larger amounts of raw material with our industrial sized spiral Jetmill in our Toll Processing Plant in Kammern to the necessary fineness followed by packaging according to customer requirements.

OUR TEAM

Dr. Jürgen Roth

CEO

j.roth@powder-maker.com

DI Erich Streibl

General Manager

e.streibl@powder-maker.com

DI Veronika Mayer

Application Manager & Sales

v.mayer@powder-maker.com

Mag. Daniela Roth

Financial Director

d.roth@powder-maker.com

Astrid König

Administration

a.koenig@powder-maker.com

Anita Seereiter

Administration

a.seereiter@powder-maker.com

Martin Milchrahm

Maintenance Supervisor

m.milchrahm@powder-maker.com

Gerfried Kölbl

Production Assistance

g.koelbl@powder-maker.com

Martin Moder

Project Assistance

m.moder@powder-maker.com

Sebastian Roth

Project Assistance

s.roth@powder-maker.com

HISTORY

1993

- Formation of PMT-Gesteinsvermahlungstechnik

- Development and construction of first spiral Jetmill with integrated classifier

- Installation of first prototypes

1995

- Acquisition of Zyklontechnik from VOEST Alpine Krems Finaltechnik

1996

- Development of the integrated rotor-motor-unit

1997

- Foundation of PMT-Zyklontechnik GmbH

- Construction of first pilot plant in Leoben

1999

- Foundation of PMT-Jetmill GmbH

2005

-

Formation of Industriepark Kammern GmbH

-

Relocation to Kammern, construction and installation of toll grinding center

2009

- Formation of PMT Powder Processing GmbH

2014

- Formation of Holding PMT Powder Maker Group and merger of all companies

- Installation of the second production plant including silo handling and storage building II

2016

- Development of energy efficient EEU System

(Enhanced Energy Utilization)

2017

- Installation of the third production plant

COMPANY STRUCTURE

PMT Powder Maker Group GmbH

PMT Powder Processing GmbH

Toll Processing Center

Toll grinding

Toll classifying

PMT-Jetmill GmbH

Jetmill with integrated classifier

Jet Classifier as stand-alone unit

Engineering for industrial

minerals processing

QUALITY AND ENVIRONMENT

Sustainable to the future

We are aware of our national and international customer’s high quality requirements and social demands. We place great importance on the future of our children and as a company that is based in the midst of the alps we feel a great commitment to the environment.

According to our company policy we commit ourselves to design technologies, products and processes which are socially, ecologically and economically sustainable.

A further step in our philosophy, is the implementation of our quality management system, according to ISO 9001, as well as our environmental management system according to ISO 14001.

MISSION

Our guiding principles are based on a lived environmental, safety and business policy

The protection of human beings has highest priority, therefore we follow all our liabilities to ensure the safety and health of our employees and of all third parties.

We ensure we avoid each accident or incident, which causes any damage to goods or could cause environmental contamination, together with the goal of increasing our production process efficiency.

The continuous development and improvement of our attempts is evident. All employees are requested to share these thoughts through active notification and consequent realization of the required actions.

The development and use of new technologies combined with well known processing steps guarantees a stabile and healthy growth of the company.

We want to fulfil all our social obligations. This applies for both our employees as well as our customers.

Our cooperative relationship with our customers and suppliers is based on confidence, which we also put into our employees.

We invest continuously into our future – but we also want to preserve the created. Only economic success enables creativity and development.

Our implemented quality and environmental management system according to the regulations of ISO 9001 and ISO 14001 supports us in pursuing and achieving our objectives.