Company

Who we are

In this area, we have set new standards in terms of energy efficiency and product fineness with our spiral jet-mills, even in the borderline area of dry grinding.

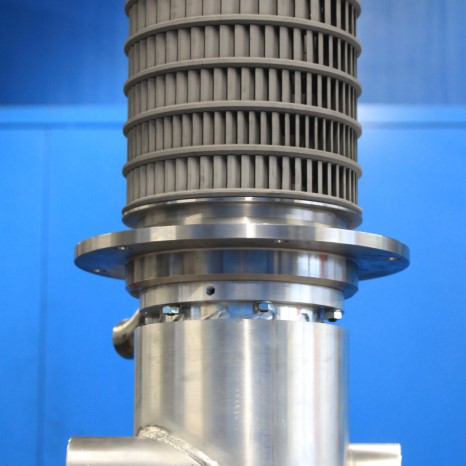

All units have in common the integrated dynamic classifier, the so-called rotor-motor unit.

Classifier discs made of a high-strength aluminum alloy are mounted on the high-frequency motor developed in-house, which allows circumferential speeds of up to 190 m/s.

The newly developed EEU system “Enhanced Energy Utilization” has achieved a reduction in specific energy consumption of up to 30% compared to other ultra-fine grinding systems.

For customers who are experiencing a short-term capacity bottleneck or who are not yet able to accurately assess the market potential of a new product, we also offer the option of grinding larger quantities of your raw materials to the desired fineness on our industrial-sized spiral jet mill in our toll grinding facility and packaging them according to customer requirements.

Our team

History

- Foundation of PMT-Gesteinsvermahlungstechnik

- Construction of the first spiral jet mill with integrated classifier

- Installation of the first prototypes

- Purchase of the cyclone technology division of VOEST Alpine Krems Finaltechnik

- Development of the integrated rotor-motor unit

- Foundation of PMT-Zyklontechnik GmbH

- Construction of the first pilot plant in Leoben

- Foundation of PMT-Jetmill GmbH

- Foundation of Industriepark Kammern GmbH

- Relocation to the Kammern site, construction of the toll grinding center

- Establishment of the holding company PMT Powder Maker Group GmbH and merger of all companies

- Construction of the second grinding plant including silo filling and warehouse II

- Development of the energy-efficient EEU system (Enhanced Energy Utilization)

- Construction of the third grinding plant

- Development of a concept for co-grinding

- Development of a system for dosing additives

- Foundation of PMT Power Trading GmbH

- Sale of the Kammern toll grinding center to a partner

Quality and environment

Sustainable into the future

In accordance with our mission statement, we are committed to ensuring that our industrial processes and products are designed to be socially, ecologically, and economically sustainable.

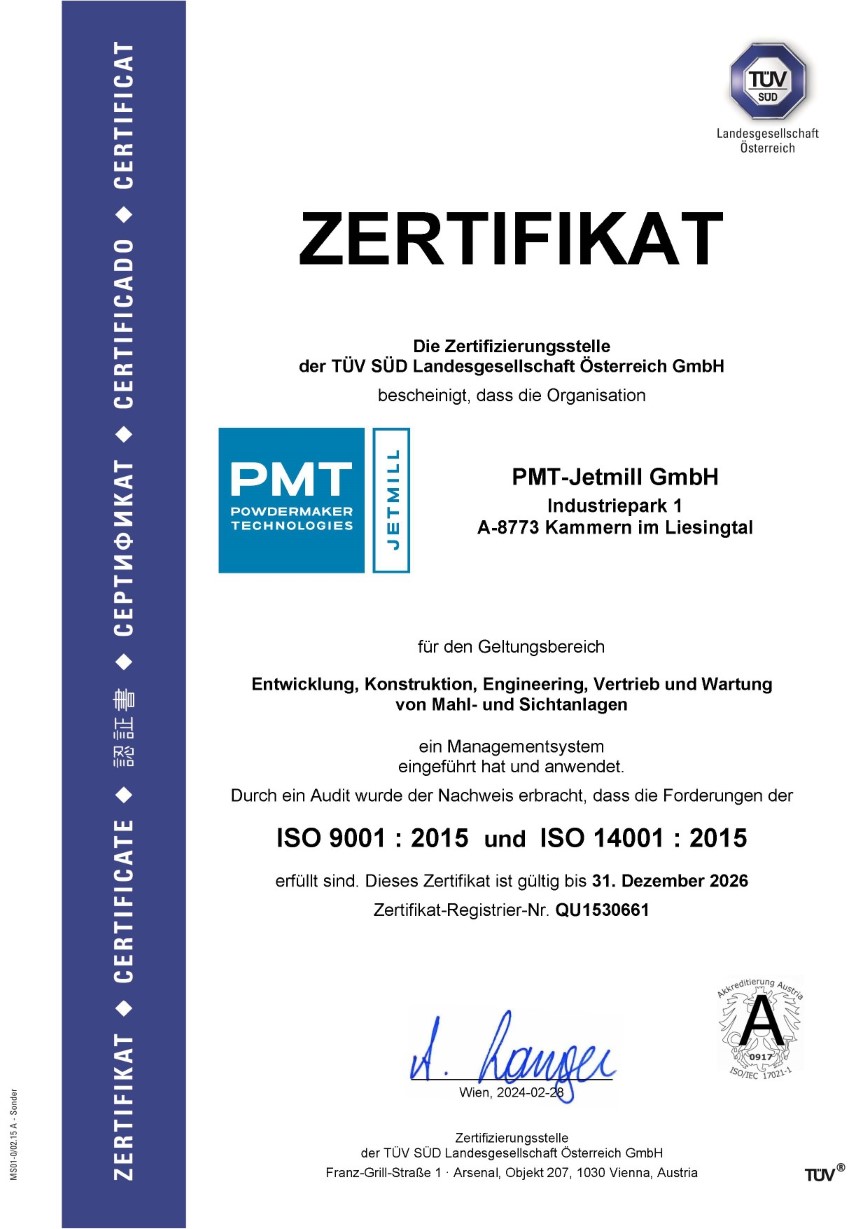

One step towards this is the implementation of a quality management system in accordance with ISO 9001:2015 and an environmental management system in accordance with ISO 14001:2015.

Mission

Our mission statement is based on a practical environmental, safety, and economic policy.

We also strive to prevent any accidents or incidents that could result in property damage, environmental damage, pollution, or contamination, and to do everything we can to increase the efficiency of our production processes.

We consider the continuous development and improvement of our efforts to be a matter of course. All employees are called upon to actively participate in this by reporting incidents and consistently implementing measures.

Our integrated quality and environmental management system supports us in implementing our goals.