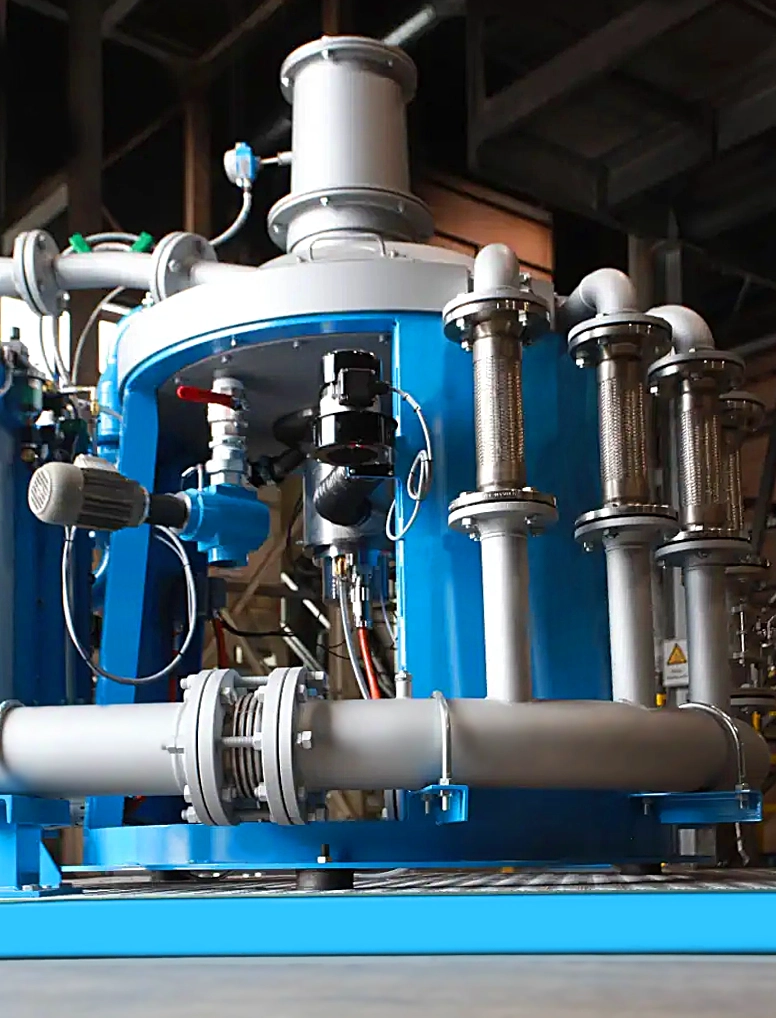

Plant

Two keys to your powder performance

Jet mill

Fine and ultra-fine grinding –

with narrow particle size distribution, energy-efficient, reproducible and scalable

from testing to series production.

Ultrafine separator

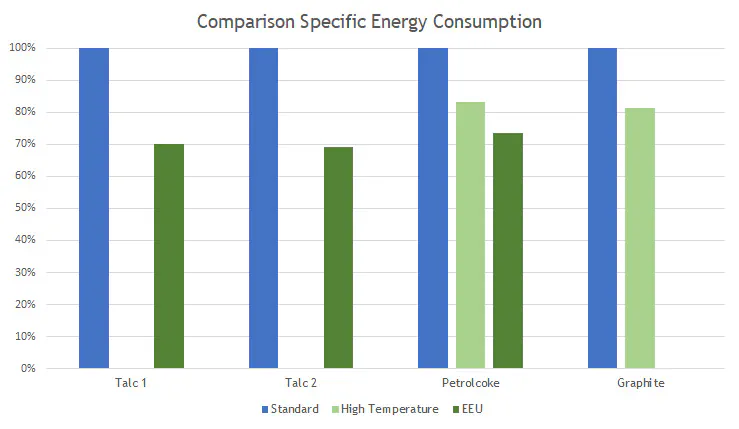

30% energy savings through Enhanced Energy Utilization EEU SYSTEM

EEU SYSTEM

Precision & efficiency up to 190 m/s

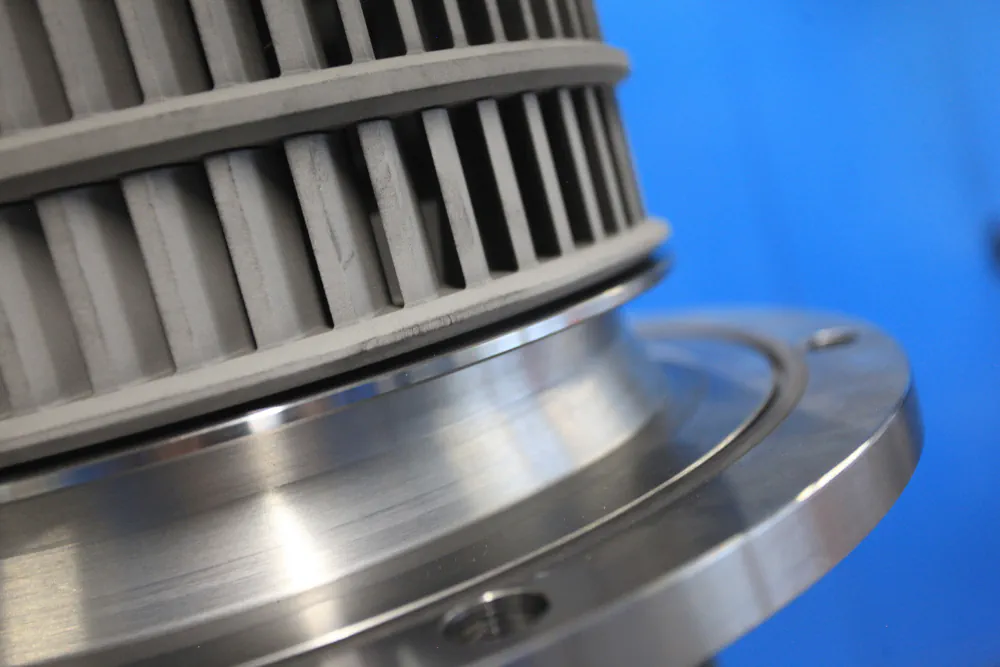

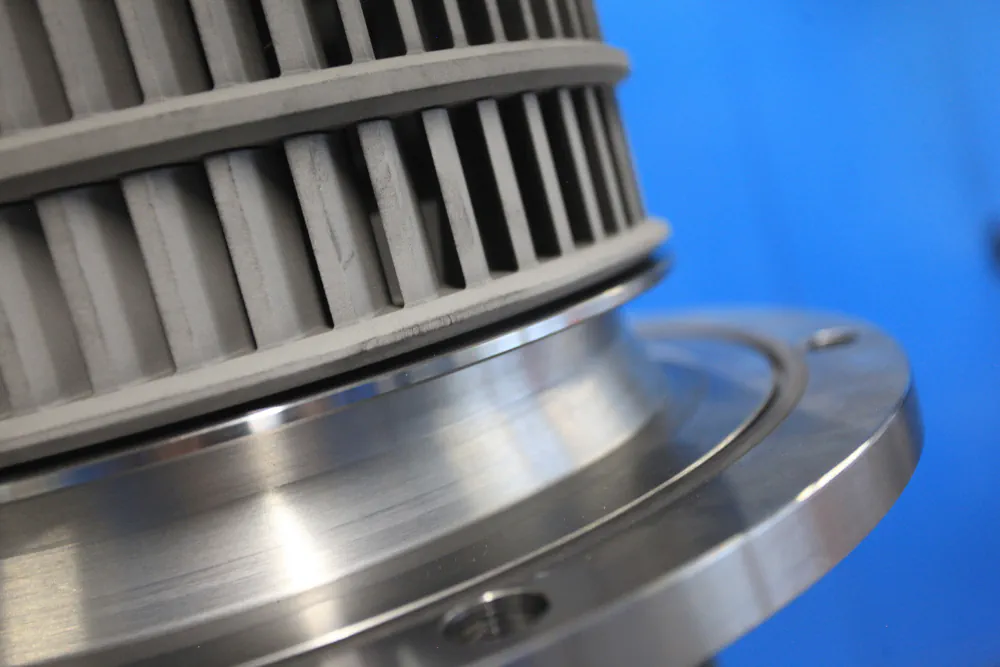

Rotor motor unit

The rotor is built on a high-speed motor developed in-house with a special maintenance-free bearing system.

Precision & efficiency up to 190 m/s

Rotor motor unit

Extensive aerodynamic research led to the patented shape of the rotor discs and, together with a perfectly matched mechanical concept, enables circumferential speeds of up to 190 m/s to be achieved.

The rotor is built on a high-speed motor developed in-house with a special maintenance-free bearing system.

Fully automatic process control

Load-controlled, stable feeding

Fully automatic unmanned operation

Real-time monitoring with history recording

Maximum availability, minimum downtimes

Maintenance

The modular rotor-motor unit is completely disassembled, cleaned and reassembled with new high-performance bearings during a service. Individual rotor discs are replaced or reused depending on the degree of wear.