Jet-Mill

New standards in product fineness

Energy-efficient ultra-fine grinding

with precise classification

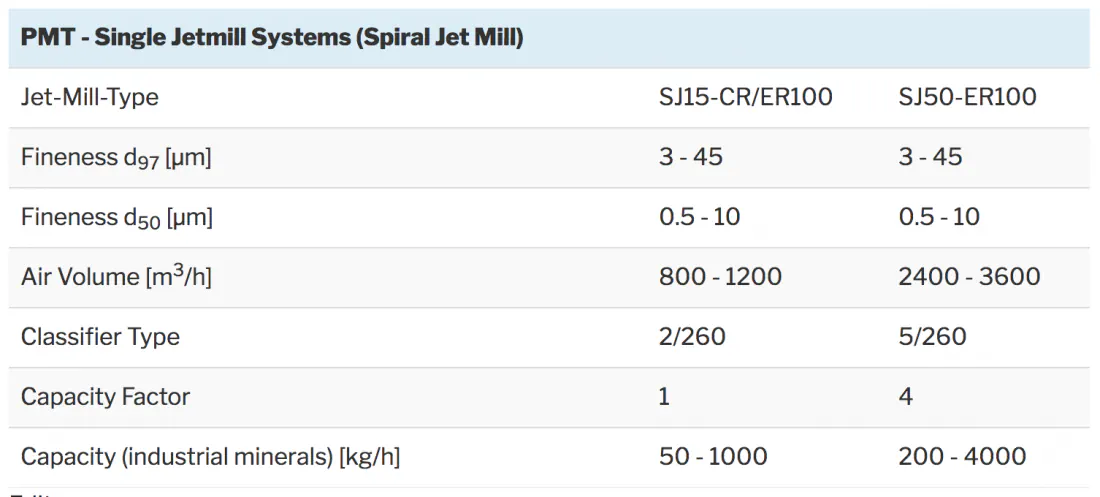

The integrated dynamic classifier, known as the rotor-motor unit, allows peripheral speeds of up to 190 m/s with rotor discs made of a high-strength aluminum alloy. This enables products with particle sizes in the low micrometer range and, depending on the material, even below 1 µm.

The fineness can be easily adjusted by changing the classifier speed. The specially developed feed rate control, together with the optimized grinding air nozzles, ensures optimum utilization of the available energy.

In addition, a continuous discharge device allows unwanted, hard-to-grind impurities (e.g., quartz) to be removed from the grinding chamber, thus significantly reducing their proportion.

More than grinding

Process integration in ultra-fine grinding

Co-grinding – precise, homogeneous composition

Defined recipe setting directly in the grinding process

Homogeneous distribution of all materials across the entire particle size distribution

Effective wear protection

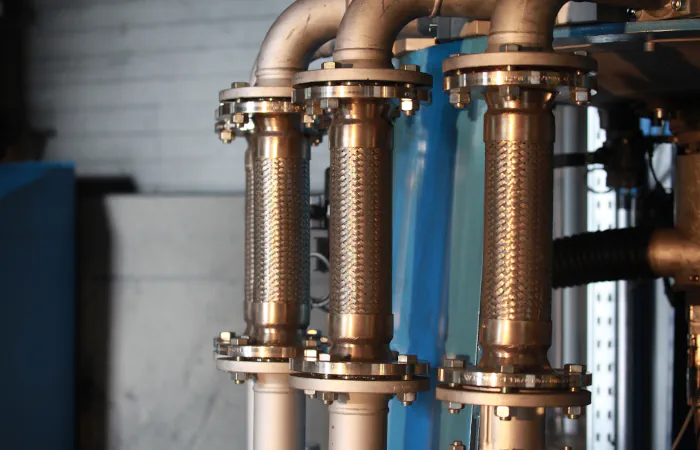

One option is CPS1 welded armor, which is applied directly to highly stressed surfaces with a layer thickness of approx. 3 mm. The hard-alloy armor forms a tough, hard wear zone with very good adhesion, significantly reduces material wear, and stabilizes the flow geometry.